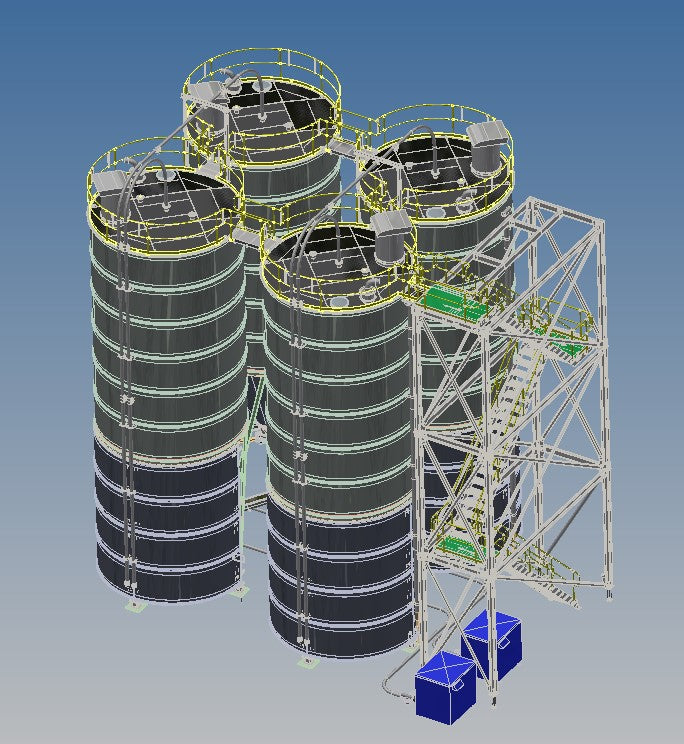

Custom Semolina Silos

Overview

The customer was looking for additional storage of semolina and polenta raw materials at their food manufacturing facility in QLD.

Details

400 m3 of storage and subsequent dosing of a processed grain ingredient used in food manufacture. Food-grade internal finishing was achieved through Kotzur’s unique smooth wall silo design in a fully stainless-steel construction for all contact surfaces.

The silos incorporate pneumatic filling capability, and inventory management through mounting on load cells. Access was provided to the roof platform through a stair access independent of the silos and conforming to AS 1657. The silos are discharged through a proprietary design plane flow hopper, permitting a silo outlet diameter greater than the arching dimension of the material. This also enables interfacing with a screw feeder, configured to promote an even drawdown of material; critical to minimising the probability of eccentric silo discharge.

The feeder was designed to deliver a known volumetric flow rate of material, giving close control over the input of product into the process. At the request of the client, the silos were fitted with skirting; custom designed and professional in its presentation. All structural and mechanical equipment in this project was designed and will be manufactured locally, providing a responsive service to the client.